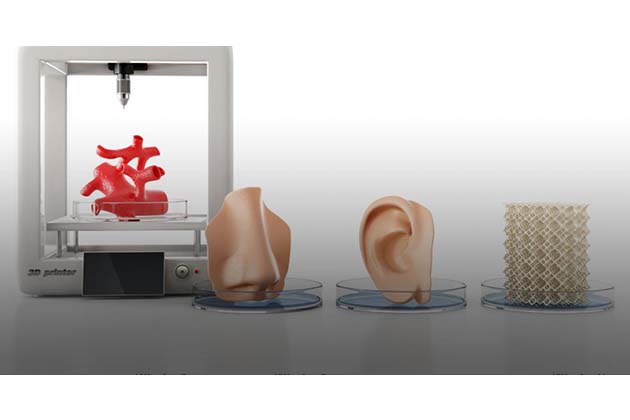

In a major advancement in3D bioprinting technique, cells and tissues have been created to behavelike in their natural environment so as to construct ‘real’ biological structures

3D printing is a procedure in which a material is added together and thus joined or solidified under digital control of a computer to create a three-dimensional object or entity. Rapid Prototyping and Additive Manufacturing are the other terms used to describe this technique of creation of complex objects or entities by layering material and gradual built up – or simply an ‘additive’ method. This remarkable technology has been around for three decades after being officially discovered in 1987, only recently it has been thrusted into limelight and popularity as not just being a means of producing prototypes but rather offering full-fledged functional components. Such is the potential of possibilities of 3D printing that it is now driving major innovations in many areas including engineering, manufacturing and medicine.

Different types of additive manufacturing methods are available which follow the same steps to achieve the final end result. In the first crucial step, design is created using CAD (Computer-Aided-Design) software on computer–called a digital blueprint. This software can predict how the final structure will turn out and also behave, thus this first step is vital for a good result. This CAD design is then converted into a technical format (called a .stl file or standard tessellation language) which is required for the 3D printer to be able to interpret instructions of design. Next, 3D printer needs to be set up (similar to a regular, home or office 2D printer) for the actual printing – this includes configuring the size and orientation, opting for landscape or portrait prints, filling up the printer cartridges with the right powder. The 3D printer then starts the printing process, gradually building up the design one microscopic layer of the material at a time. This layer is typically around 0.1mm in thickness though it can be customized to suit a particular object being printed. The entire procedure is mostly automated and no physical intervention is required, only periodic checks to ensure correct functionality. A particular object takes several hours to days to complete, depending on the size and complexity of the design. Further, since it’s an ‘additive’ methodology, it is economical, eco-friendly (with no wastage) and also provides much greater scope for designs.

The next level: 3D Bioprinting

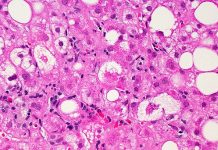

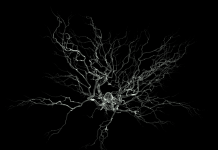

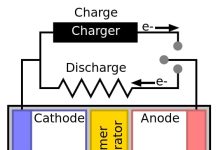

Bioprinting is an extension of traditional 3D printing with the recent advancements enabling 3D printing to be applied to biological living materials. While 3D inkjet printing is already being used to develop and manufacture advanced medical devices and tools, a step further needs to be developed to print, view and understand biological molecules. The crucial difference being that unlike the inkjet printing, bioprinting is based on bio-ink, which is comprised of living cell structures. So, in bioprinting, when a particular digital model is input, the specific living tissue is printed and built up layer by cell layer. Because of the highly complex cellular components of the living body, 3D bioprinting is progressing slowly and complexities such as the choice of materials, cells, factors, tissues are posing additional procedural challenges. These complexities can be addressed by broadening understanding by integrating technologies from interdisciplinary fields e.g. biology, physics and medicine.

Major progress in bioprinting

In a study published in Advanced Functional Materials, researchers have developed a 3D bioprinting technique which uses cells and molecules normally found in natural tissues (their native environment) to create constructs or designs that resemble ‘real’ biological structures. This particular bioprinting technique combines ‘molecular self-assembly’ with ‘3D printing’ to create complex biomolecular structures. Molecular self-assembly is a process by which molecules adopt a defined arrangement on their own to perform a specific task. This technique integrates ‘micro- and macroscopic control of structural features’ that ‘3D printing’ provides with the ‘molecular and nano-scale control’ enabled by ‘molecular self-assembly’. It uses the power of molecular self-assembly to stimulate the cells that are being printed, which is otherwise a limitation in 3D printing when regular ‘3D printing ink’ does not provide this means for this.

Researchers ‘embedded’ structures in ‘bio ink’ which is similar to their native environment inside the body making the structures behave as they would in the body. This bio-ink, also called the self-assembling ink helps to control or modulate chemical and physical properties during and after the printing, which then allows to stimulate cell behaviour accordingly. The unique mechanism when applied to bioprinting allows us to make observations on how these cells work within their environments, thereby giving us a snapshot and understanding of real biological scenario. It raises the possibility of building 3D biological structures by printing multiple types of biomolecules capable of assembling into well-defined structures at multiple scales.

The future is very hopeful!

Bioprinting research is already being used to generate different types of tissue and thus can be very important for tissue engineering and regenerative medicine to address the need for tissues and organs suitable for transplantation – skin, bone, grafts, heart tissue etc. Further, the technique opens up a wide array of possibilities to design and create biological scenarios like complex and specific cell environments to enable prosperity of tissue engineering by actually creating objects or constructs -under digital control and with molecular precision- which resemble or mimic tissues in the body. The living tissue, bone, blood vessels and, potentially and whole organs models are possible to create for medical procedures, training, testing, research and drug discovery initiatives. Very specific generation of customized patient-specific constructs can help in designing accurate, targeted and personalised treatments.

One of the biggest obstacles for bioprinting and 3D inkjet printing in general has been the development of an advanced, sophisticated software to meet the challenge at the first step of printing – creating an appropriate design or blueprint. For instance, the blueprint of non-living objects can be created easily but when it comes to creating digital models of say, a liver or heart, its challenging and not straightforward like most material objects. Bioprinting definitely has multitude advantages – precise control, repeatability and individual design but is still plagued with several challenges – the most important one being inclusion of multiple cell types in a spatial structure since a living environment is dynamic and not static. This study has contributed to advancement of 3D bioprinting and lot of obstacles can be removed by following their principles. It is clear that the real success of bioprinting has several facets attached to it. The most crucial aspect which can empower bioprinting is development of relevant and appropriate biomaterials, enhancement of the resolution of the printing and also vascularisation to be able to successfully apply this technology clinically. It does seem impossible to ‘create’ fully functioning and viable organs for human transplant by bioprinting but nevertheless this field is progressing fast and plenty of developments are on the forefront now in just a few years. It should be achievable to overcome most of the challenges attached with bioprinting since researchers and biomedical engineers are already on the path to successful complex bioprinting.

Some issues with Bioprinting

A critical point raised in the field of bioprinting is that it is almost impossible at this stage to test the efficacy and safety of any biological ‘personalised’ treatments being offered to patients using this technique. Also, costs associated with such treatments is a big issue especially where manufacturing is concerned. Though it is very much possible to develop functional organs that can replace human organs, but even then, currently there is no fool proof way to assess whether the patient’s body will accept new tissue or the artificial organ generated and whether such transplants will be successful at all.

Bioprinting is a growing market and will focus on the development of tissues and organs and maybe in a few decades new outcomes would be seen in 3D printed human organs and transplants. 3D bioprinting will continue to be the most important and relevant medical development of our lifetime.

***

{You may read the original research paper by clicking the DOI link given below in the list of cited source(s)}

Source(s)

Hedegaard CL 2018. Hydrodynamically Guided Hierarchical Self-Assembly of Peptide-Protein Bioinks. Advanced Functional Materials. https://doi.org/10.1002/adfm.201703716